The OptimaInsert Story

A true Story

The beginning of OptimaInsert lies a few years back. A larger printing house in the Berlin area received a new order.

The team around the production manager, let’s call him Tom, was to produce a free weekly newspaper with a circulation of over 1.53 million copies per week on two new inserting lines with 18 feeders each.

To make it even more sophisticated, there were 33 local editions. Within one production, about 6.0 million inserts were to be inserted. In the year, the total number of inserts was over 250 million. There was a window of just 33 hours to produce the entire job.

Tom analyzed the production data and quickly found more startling facts about the new production. There were to be 37 different inserts plugged in. This resulted in 330 different combinations and up to 11 inserts running simultaneously.

Since Tom was a savvy PC user, he immediately began planning with a spreadsheet program. It couldn’t be that hard! It quickly became apparent that planning over the entire production period meant a very, very large amount of work, and if there were even the smallest errors, they could start all over again. Since different inserts have to run on certain feeders due to their weight or format, this made the task even more difficult. Tom’s team was under enormous pressure before each production, as there were only a few hours available for planning.

During the first productions, it quickly became apparent that the planned schedule was soon nothing more than wastepaper. People started planning as far as they could, stopped production and planned for the next few hours. This did not correspond to the production schedule and effort envisaged by the printing facility management.

In some cases, the production target was missed by 24 hours. Everyone can work out that the actual costs significantly exceeded the planned costs. Tom’s team was at times in despair. They did not want to work like this for the next months and years.

Tom, as a person with an affinity for technology, was sure that only software-supported planning could steer this production on a successful course.

There was this new software “OptimaInsert” which promised to solve all his problems. Tom organized the software and was able to achieve the required time and quality targets right from the start due to the intuitive program.

The very next day he gathered his colleagues and showed them the solution to their problem. Within less than an hour, the planning for production was done.

The success of the software was so convincing, however, that Tom and his team were rewarded with a bonus from the faciliy’s management. Thanks to the new software, line output increased by an average of 3,800 copies per hour while the waste rate was reduced. Production time was reduced by five hours per line. The planning phase finally amounted to 30 minutes and no longer several hours.

Subsequently, many suggestions from practical operation were integrated in the further developed versions of OptimaInsert. Today, Tom can no longer imagine order and machine planning without OptimaInsert.

Planning with OptimaInsert

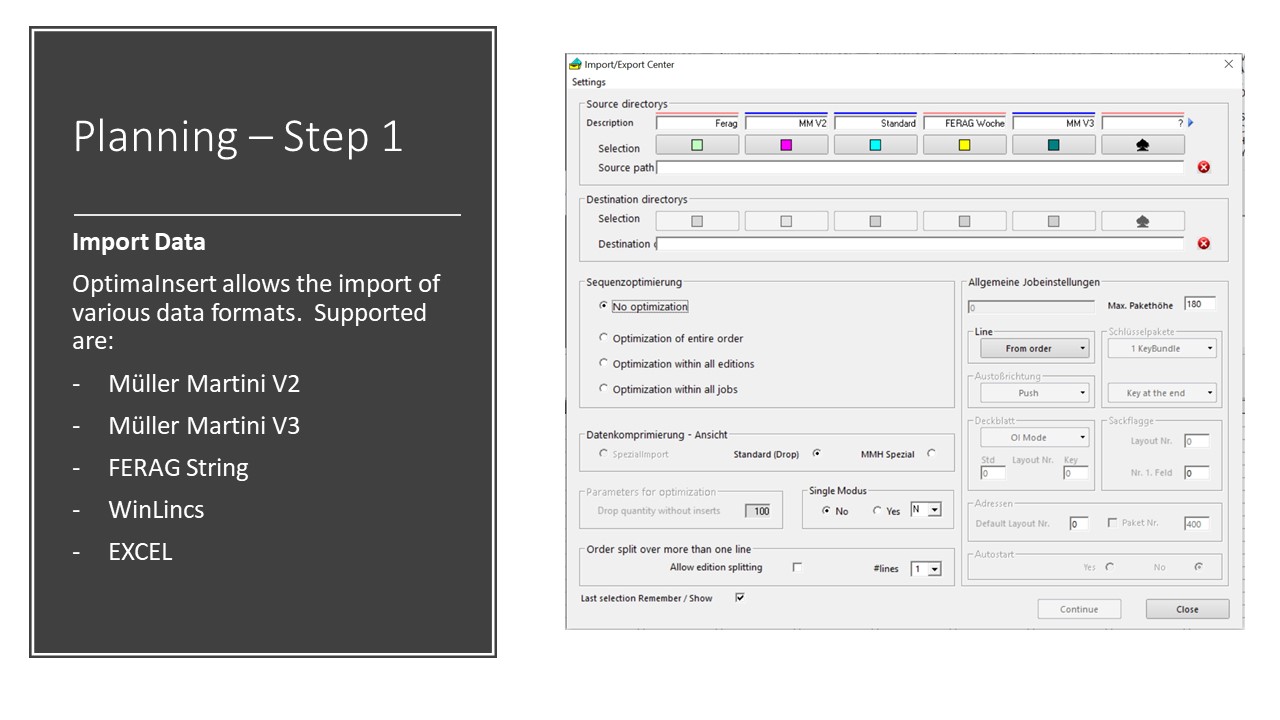

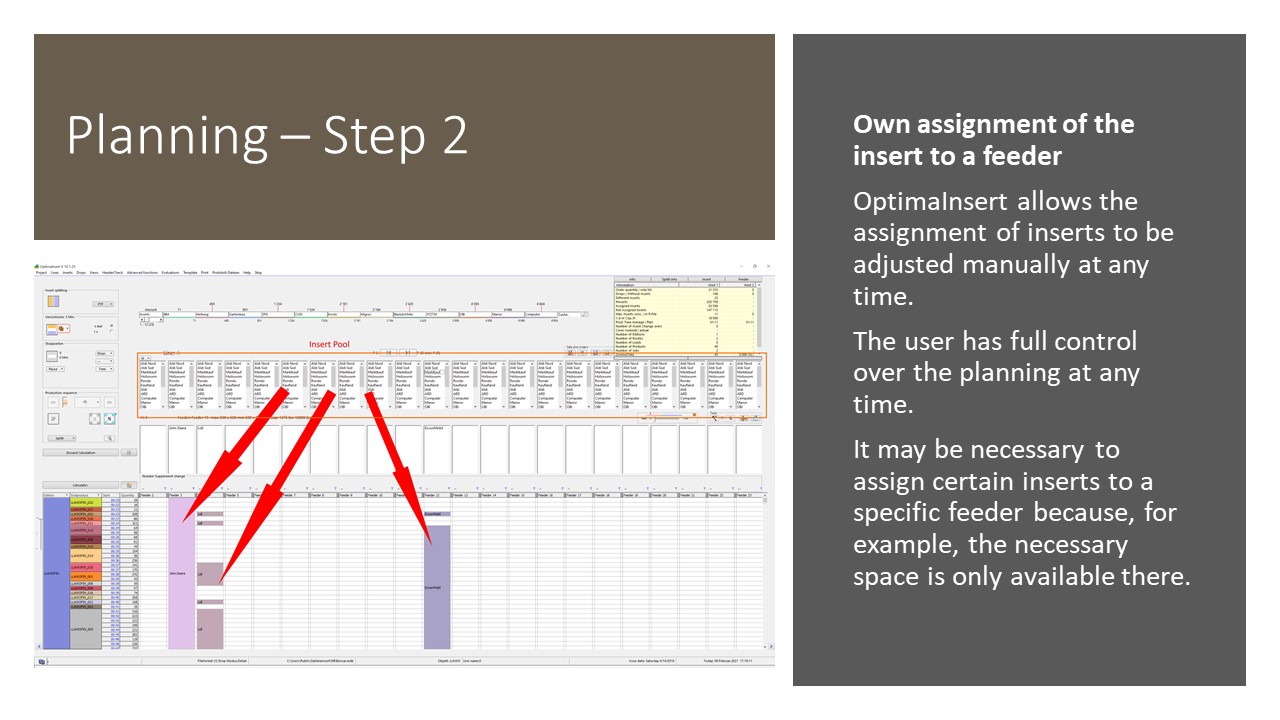

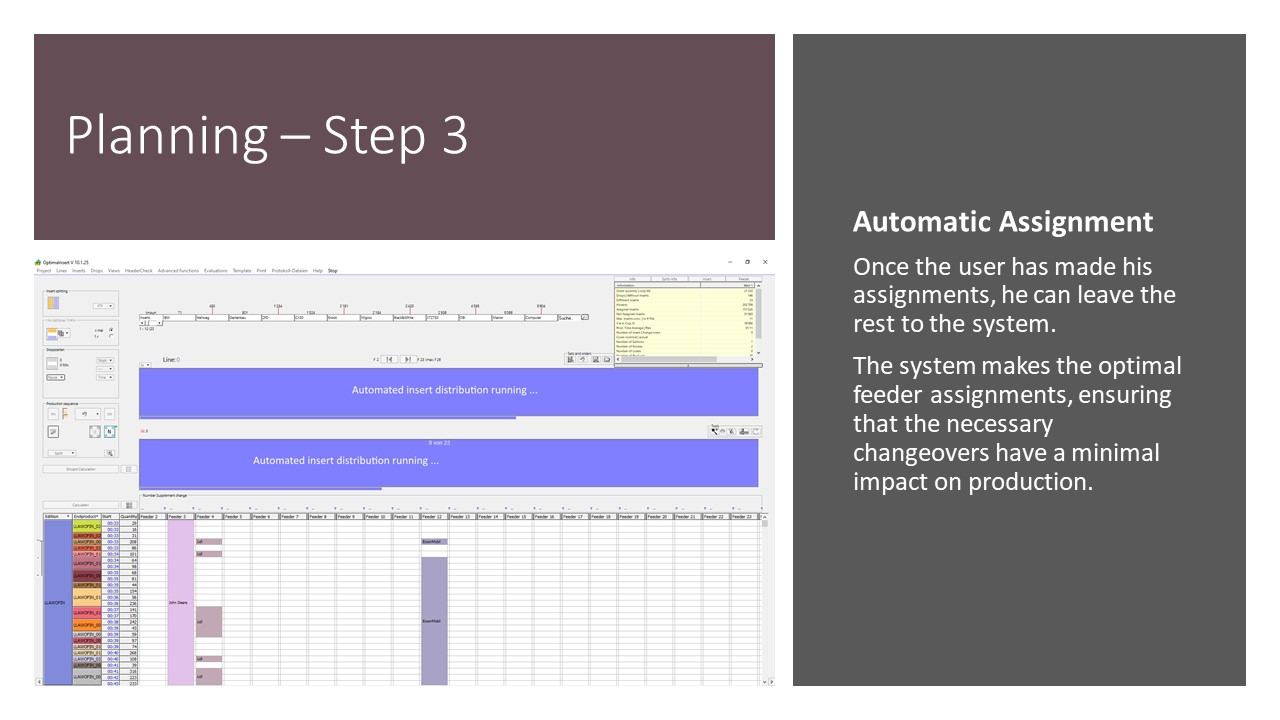

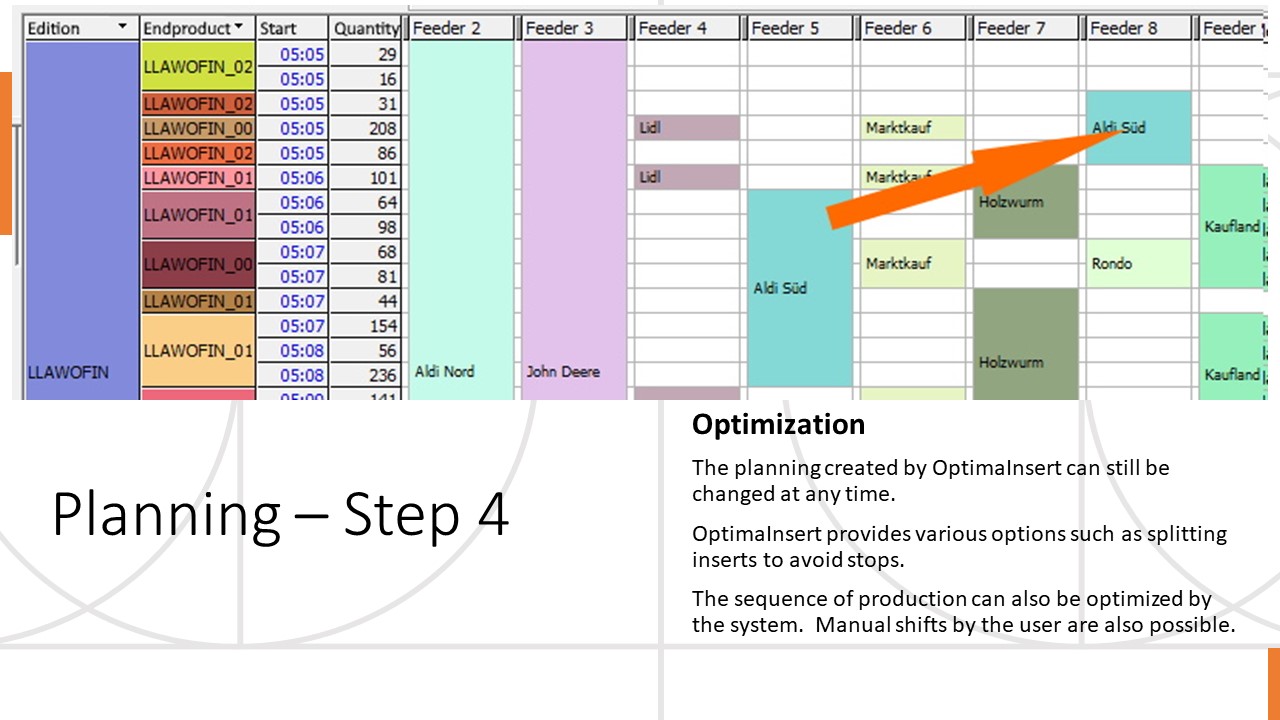

Planning with OptimaInsert is done in a few steps. Every mailroom employee with some experience is able to use OptimaInsert successfully within shortest time.

OptimaInsert functions

OptimaInsert offers a wide range of functions that support the user in making his production as optimal as possible. Whether in automatic or manual planning, the user has full control – at all times.

You will find below a short description of the most important functions.

OptimaInsert Clients

“The production of 1.5 million copies and over 300 different insert combinations would be impossible to manage in the given time frame without a system like OptimaInsert.”

“We produce our ad papers

Due to the small zones, we produce our ad papers with large circulation numbers according to insert combinations in order to be able to process as many inserts as possible by machine. Thanks to the combination of automatic and manual program functions, we quickly achieve optimum results while always keeping the overview – a real reduction in workload and a great time saver.”

“Thanks to OptimaInsert, we were able to increase the performance of the plant by 25%”.

“Using OptimaInsert means bringing transparency and security to the planning and production processes. Thus, OptimaInsert became indispensable in our company. Last but not least, the OI developers read our wishes from our lips.”

“OptimaInsert and a new high-performance inserting system form a dream team with which our company has mastered the transformation from analog to digital production. Previously complex processes are intelligently digitized through the use of OptimaInsert and thus significantly shortened, streamlined or even superfluous. This applies both before and during production – especially for advertising newspapers with a high number of inserts. Service and support also leave nothing to be desired.”

Are you interested in OptimaInsert? We are looking forward to your mail or your call.

EQUAL Software AG

Bachstrasse 38

CH-4654 Lostorf

Tel: +41 62 752 10 00